Meet the talented refurbishment engineers across our national Conservation Stations.

These local refurbishment centres including Leicester, York, Gateshead, Edinburgh, Aberdeen, Inverness, Croydon, Rochester, and Southampton, play a crucial role in extending the life of lightly used MFDs.

By refurbishing machines close to where they’re needed, our teams reduce transportation distances and support Agilico’s circular future.

Each engineer brings a passion for excellence, backed by strong technical skills and decades of experience, ensuring that our refurbished devices meet high standards of performance and sustainability.

These talented individuals have an impressive range of hobbies and interests outside of work and bring the same passion and dedication to their roles.

Discover what makes them so special and how they contribute to our company’s success.

Midlands

Our team, based in Leicester, operates out of our first purpose-built refurbishment centre, a hub of innovation and activity.

Led by Operations Manager Aron Bacon, the team consists of a dynamic group of experts, including Workshop Engineers Louis Dawson, Steve Critchley, Colin Bannister, Alex Reeves, and Jack Cox, alongside Installation & Workshop Engineers Richard Thompson and Chris Lane.

The team shares a strong bond, especially around their passion for Formula 1. Every race weekend brings ‘F1 Friday,’ where they proudly wear their favourite team shirts, and they’ve even launched an F1 fantasy league involving staff from other departments, fostering friendly competition and cross-team collaboration.

Aron, Richard, and Chris also share a love for aquatics, with Aron setting up a small aquarium in his office. The tank, home to two clownfish amusingly named Konica and Minolta, has become a centrepiece that brings enjoyment to the whole team.

They’re an active bunch, too. Louis and Steve play golf, with Steve boasting a scratch handicap, while Alex and Colin are avid mountain bikers—Colin also holds a Private Pilot’s License. Jack, the newest team member, joined in August and is a football fan, gamer, and movie enthusiast.

Lastly, we celebrate a personal milestone for Steve Critchley, who recently became a proud grandfather, adding another reason to celebrate within this thriving team!

North

With teams spread across key locations in the North of England, our operations cover a wide range of expertise and enthusiasm. At the Gateshead site, one of our newest facilities, Operations Manager Kris Robinson leads a dedicated team that includes Chris Turner, Senior Workshop Engineer, and Workshop Engineers James Lunn and Michael (Mick) Kane.

Chris is an avid Formula 1 fan, a music enthusiast, and a cycling lover who spends his free time exploring the Lake District. Mick, a passionate Newcastle United supporter, enjoys sea fishing, playing golf, and socialising when not at a game. Supporting them, local engineers Anthony Harbertson and Joseph Foster are always on hand to assist.

Further south in York, Operations Manager Richard Bayliss heads another talented team, including Senior Workshop Engineers Darrell Murray and Carl Appleby. Darrell, a Leeds United fan, enjoys hiking and wild swimming, while Carl, who supports Hull City, spends his downtime fishing. Together, they cover a vast area from Manchester to Hull, ensuring that our reach extends across the region.

Each location brings together not only technical expertise but also a deep connection to the local communities, passions, and landscapes that make our teams unique.

Scotland

Our refurbishment teams, based across Edinburgh, Aberdeen, and Inverness, cover the entirety of Scotland, ensuring our presence and expertise reach far and wide.

Led by Scott Little, the Edinburgh team combines a wealth of experience, with team members serving from 2 to 27 years. The team includes Scott Little, Workshop Manager; Laszlo Nagy, Workshop Team Leader; and Workshop Engineers Grant Gilbertson, Murray Sutherland, and Jamie Bradley. Together with four trainee engineers—Jamie McGinn, Michael Hastie, Sam Graham, and Connor Murdoch—this group is key to nurturing fresh talent and supporting our sustainability goals. Their collective interests span family time, sports, fitness, travel, and gaming, reflecting the vibrant diversity of this highly skilled workforce.

Further north, our Aberdeen team consists of Workshop Manager Phil Pirie and Trainee Douglas Scruby. Phil is a devoted Aberdeen FC fan and stays active in the gym, while also lending his support to the Bon-Accord Silver Band. Douglas, a gaming and live music enthusiast, brings his own dynamic to the team.

In Inverness, Workshop Manager David Smith, Workshop Engineer John Bisset, and Workshop Refurbishment Operative Trainee Logan Hart form the team. David’s passion for maintaining Land Rovers and caring for local village plants contrasts with Logan’s dedication to combat sports and fitness, making this a team that blends tradition and modern drive.

From the capital city to the Highlands, our teams bring a unique mix of expertise and passion to every corner of Scotland. Whether refurbishing complex equipment or developing the next generation of engineers, our presence ensures that we continue to deliver excellence across the whole of the UK.

South

The Southern Refurbishment teams at Agilico, led by Service Director Justin Nicolson, operate across multiple key locations in the South of England at Croydon, Rochester, and Southampton. Each site plays a crucial role in ensuring high-quality refurbishments and service for our customers, contributing to a network of expertise and dedication that spans the region.

The team is known for its meticulous attention to detail, with Service Engineer Marc Waters setting the standard. With around 30 years of experience, Marc, like many of his colleagues, excels in refurbishing and maintaining MFDs, ensuring every machine performs to its best. Marc’s dedication to his craft is mirrored by his commitment to staying fit and active outside of work, where he enjoys regular gym sessions.

Warehouse & Logistics Manager Lee Dennis, alongside Workshop Engineers Andy Oliver and Richard Pryer bring together a diverse range of skills. By combining extensive experience with a strong commitment to quality refurbishments. Their expertise contributes significantly to extending the life of MFDs, minimising waste, and enhancing cost-efficiency for our customers.

Lee is a dedicated family man who enjoys theatre trips and exploring the outdoors, with a particular interest in wildlife. Andy is a fan of sci-fi films and loves playing board games in his free time. Richard is passionate about real ales and takes it to the next level as a member of CAMRA (Campaign for Real Ale).

Workshop Supervisor Andy Sargent has been a key figure at Agilico for 25 years, managing local PDIs and refurbishing machines with efficiency and expertise. Andy’s passion and commitment to sustainability is evident in his efforts to harvest and reuse parts from older machines, supporting cost-effective and eco-friendly practices. A sports enthusiast, Andy is deeply involved in the English cricket Barmy Army and is an avid supporter of Southampton Football Club, with interests in travel and environmental conservation rounding out his wide-ranging hobbies.

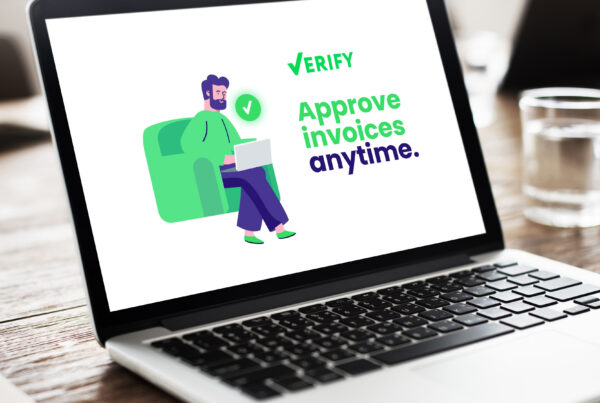

A closer look at what they do

Our expert engineers are at the heart of refurbishing our Agilico Zero range of MFDs, transforming lightly used machines into ‘as new’ devices ready to perform at their best. With decades of experience and a commitment to a quality-first approach, they ensure every device meets the highest standards.

The refurbishment process involves a thorough inspection of over 30 key components, alongside sanitising all hard drive data. Any worn or damaged parts are replaced, and every function is rigorously tested. After a final quality control check, the machine is ready for a new life. In some cases, parts are harvested for other devices, and anything that can’t be reused is responsibly recycled through our waste management partners.

Each refurbished device helps avoid at least 500 Kg of carbon, actively supporting the circular economy.

Want to see this process in action?

Watch our short video or reach out to arrange a visit to one of our national Conservation Stations and experience our commitment to quality and sustainability first hand.

Together, our refurbishment teams and sites are driving a significant shift toward sustainability by extending the life of MFDs across the UK. Each team’s dedication to refurbishing and reusing parts ensures that fewer resources are consumed, and more machines are kept in optimal working condition, minimising waste and reducing environmental impact.

As the UK’s pioneering Circular-First Managed Print Services business, Agilico is not only shaping a circular future but is also setting new standards in responsible business practices. By keeping quality and sustainability at the forefront, our teams are making a tangible difference; for Agilico, for our clients, and for the planet.

Interested?

Looking for sustainable office solutions with exceptional performance?

Get in touch today to learn how Agilico Zero refurbished devices can help your business reduce waste, save money, and support your sustainability goals with zero compromise in quality or reliability.