Print for the Planet

At Agilico, we support the worldwide effort to build a better future for people and planet.

We’re proud to be the UK’s pioneering Circular-First Managed Print Services business, leading sustainability in our sector.

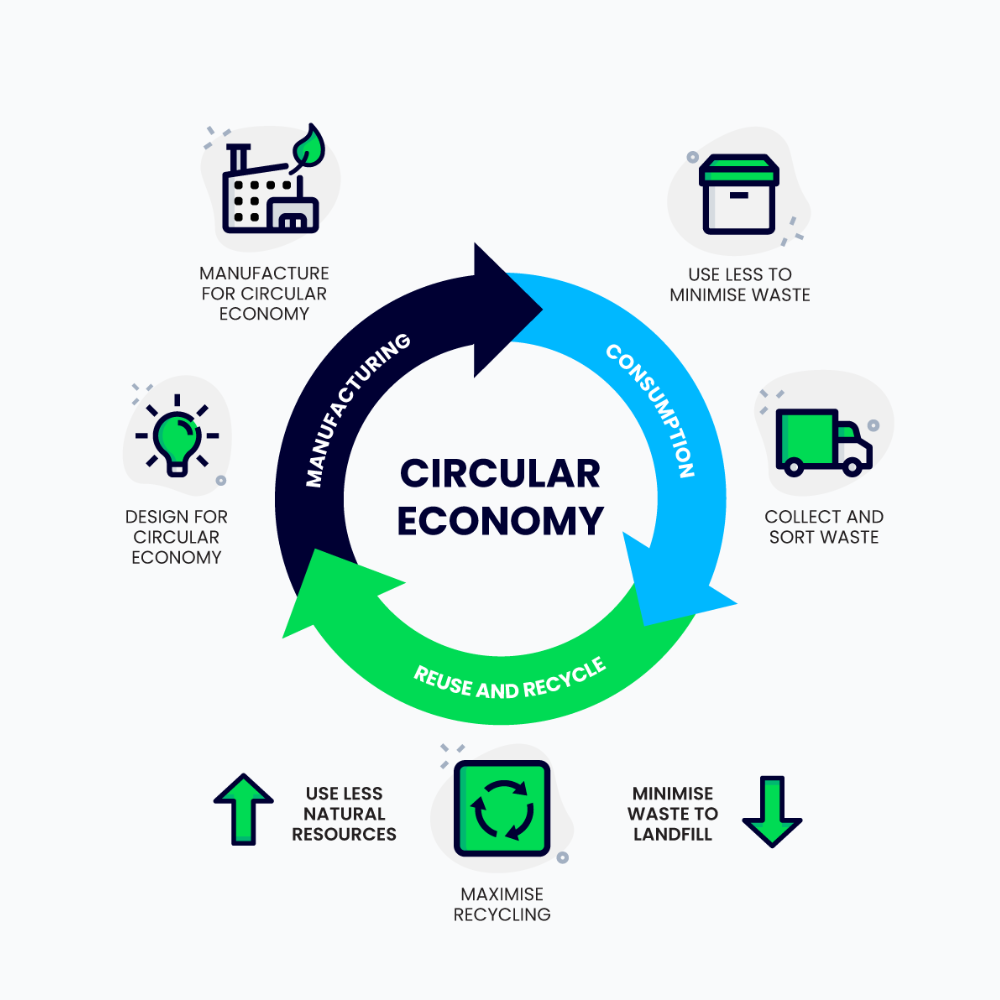

Instead of the traditional ‘take-make-waste’ model, where resources are used once and then discarded, our circular-first sustainable managed print service keeps resources in use for as long as possible, extracting their maximum value and then regenerating them into new products or materials.

Shaping a Circular Future.

Our award winning Circular-First Sustainable Managed Print Services centre around refurbishing and recycling Multi-Functional Devices (MFDs) and parts wherever possible.

In doing so, we cut carbon emissions associated with new device and parts manufacturing, reduce used waste going into landfill, and provide a more cost-effective solution for our customers.

Optimising Your Print Environment.

The first step to optimising your print environment for sustainability is to choose an Agilico Zero MFD.

By opting for refurbished devices, you not only reduce your environmental footprint but also contribute to a circular economy by extending the lifespan of technology.

This small but impactful choice sets the foundation for a greener print environment.

Out With the Old

The old ways of Managed Print Services have been built around the same generic process.

1. Raw materials are used to build a brand-new device

2. The device is shipped thousands of miles from manufacturer to customer.

3. The device is put to work, churning out paper.

4. And then it’s disposed of at the end of its life or contract term.

That’s expensive, inefficient and environmentally unfriendly.

Managed print providers must do better.

So We Are.

In With the As New

National Conservation Stations.

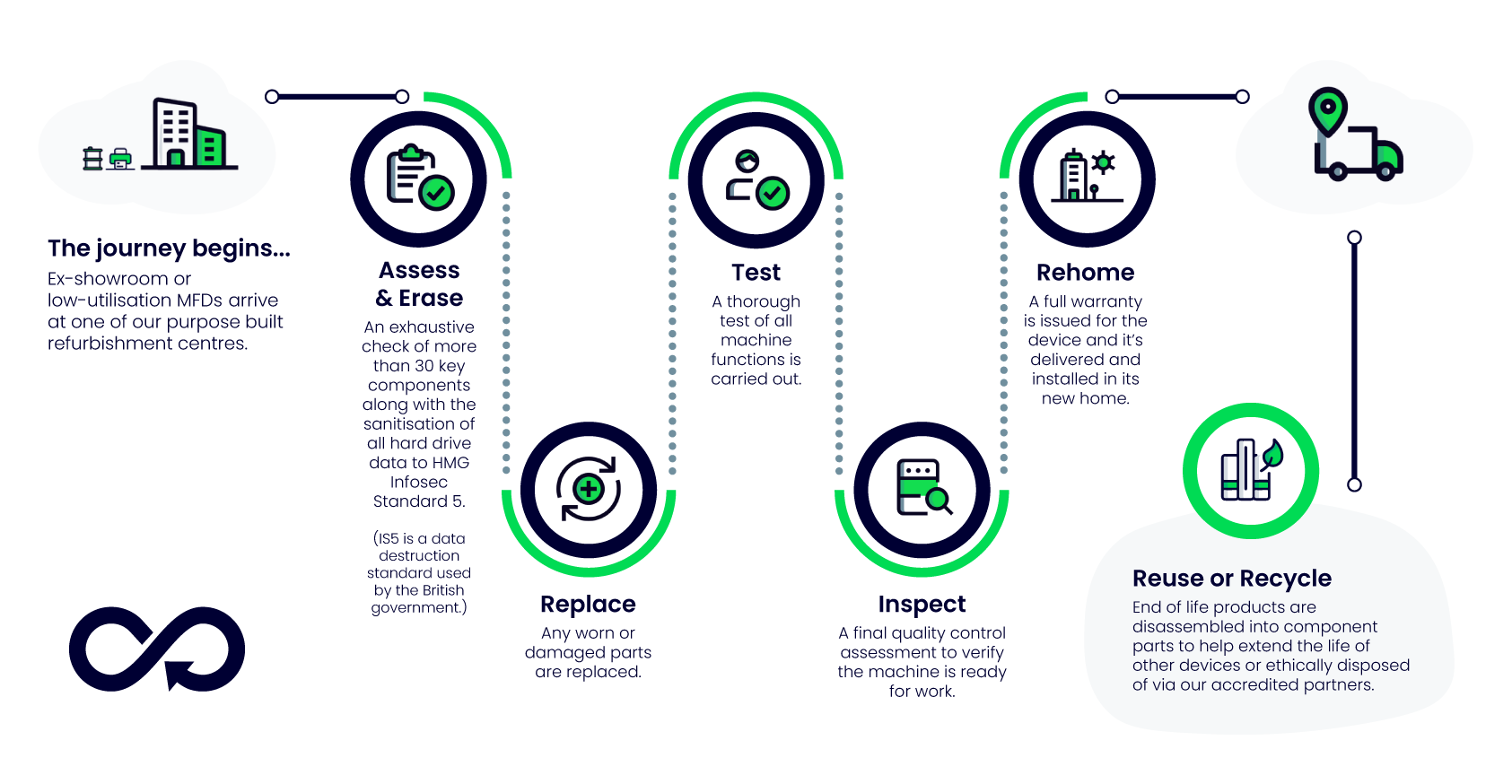

From North to South, our MFD refurbishment centres are doing great work in the circular economy.

At these sites, our qualified teams of expert engineers reclaim and refurbish ex-showroom or low-utilisation devices.

But that doesn’t mean tired old stock that’s just given a repolish.

All Agilico Zero A3 devices have on average at least 80% of their lifetime volume left.

Our engineers then conduct dozens of quality control checks and procedures to transform parts and devices back to ‘as new’ working order.

Once the refurbishment process is complete, it’s almost impossible to tell the difference between new and reused.

Harvest for the World.

Any end-of-life products that can’t be used are disassembled into component parts to help extend the life of other devices, or they’re ethically disposed of via our accredited partners.

Whether that’s breaking down devices to recover valuable resources or recycling plastics into new items, we’re committed to recycling any unusable components.

How it Works

No carbon guzzling and resource wasting manufacturing processes.

No expensive globe-trotting logistics.

With an Agilico Zero Device…

You’ll

Cut carbon emissions associated with new device and parts manufacturing. (At least 500 kg C02e).

Reduce needless used waste going into landfill.

Plus You’ll Get

A quality device with a full warranty.

A choice of device speeds.

A more cost-effective solution that performs as if it were new.

There’s a Lot to Like.

If you want an environmentally friendly, incredibly reliable, and cost-effective sustainable managed print service, optimised with innovative tech and smart printing capabilities…

Build a sustainable managed print environment, with Agilico Zero.

How Agilico Zero is helping businesses like yours

Interested?

Get set for greener printing

Complete your details below to receive ‘The Greener Way to Print’ guide, and set up a call with an Agilico team member to find out everything you need to know about our award wining Agilico Zero refurbished devices.